We make our 150 years of experience available to your benefit

At times when being young appears to have an intrinsic value, we are self-assured enough to be able to say: No, we are not really young anymore. To be more accurate, we here at Firner Trautwein look back over our 150 years of experience in the turned part manufacturing sector. Over this long period of time, we have been able to acquire the skills that have made us into one of the leading manufacturers of customer-specific precision turned parts. After all, what has always accompanied us is our strive for improvement, the urge to achieve perfection - a never-ending process. At the heart of what we do, we have always been committed to producing the best possible components precisely to the wishes and requirements of each of our customers. It is the length of time that we have been engaged in this that enables us to keep on acquiring new and even better production and machining processes, to get to know a vast array of different metals better than almost anyone else, and to make a start where others may already have decided to stop. Throughout all of this time, what sets Firner Trautwein apart is the thought we give to the future. Something that today might appear impossible is something that we seek to make happen tomorrow - which is to create your perfect turned part!

Machining materials Production / Manufacture Machinery FT Service

Machining materials

A leading force in the manufacture of customer-specific precision

We know our craft, in terms of every conceivable machining characteristic and quality of material. Just contact us and explain what you wish to accomplish. Together, we shall find the optimum solution.

Production / Manufacture

That is what we do!

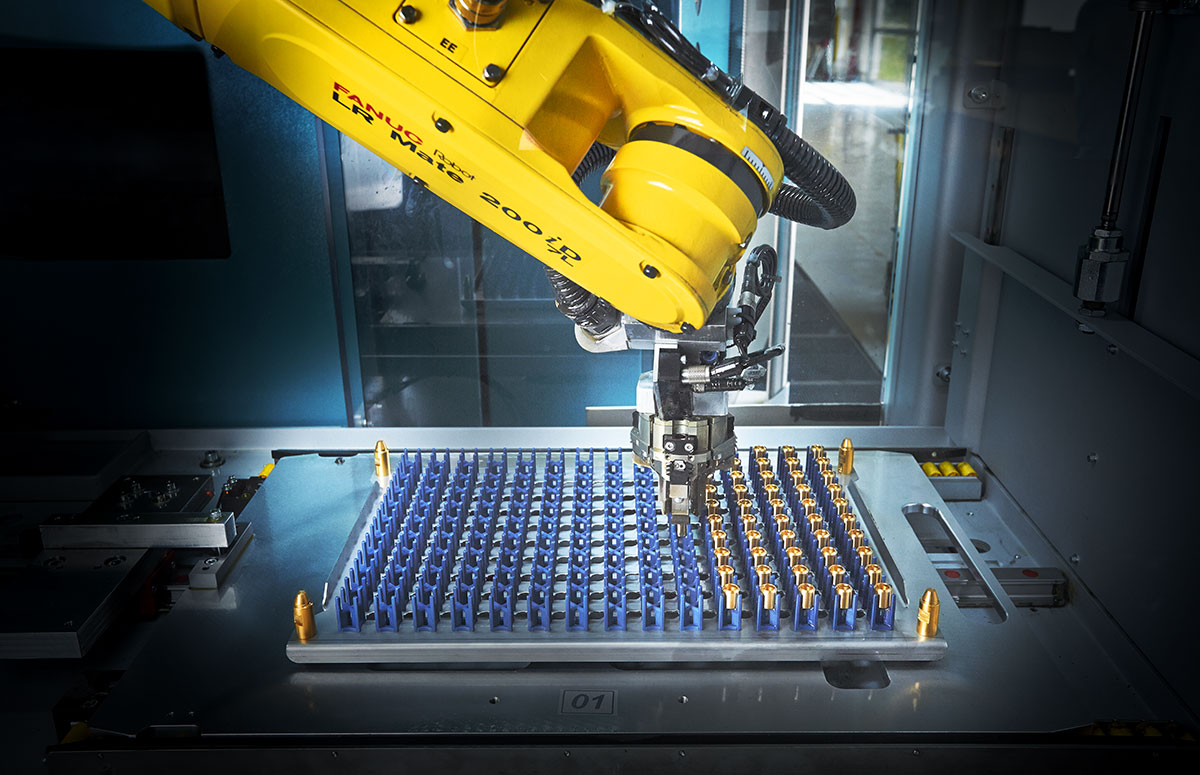

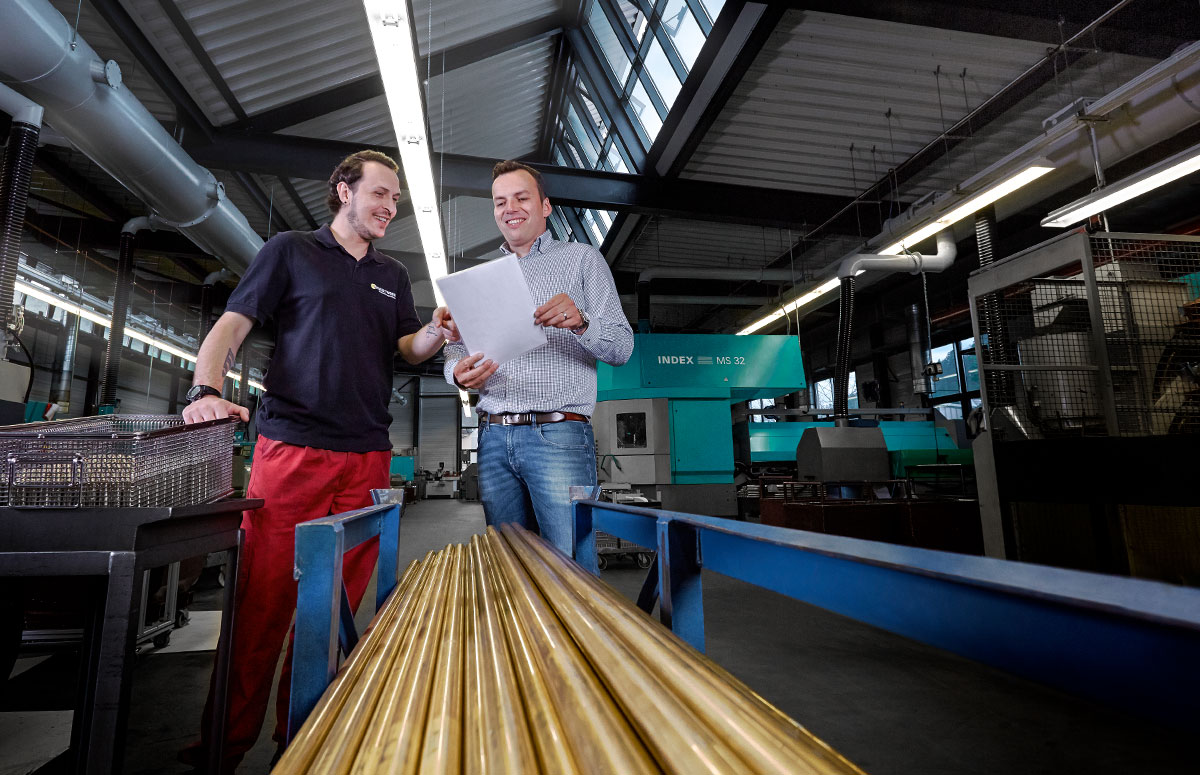

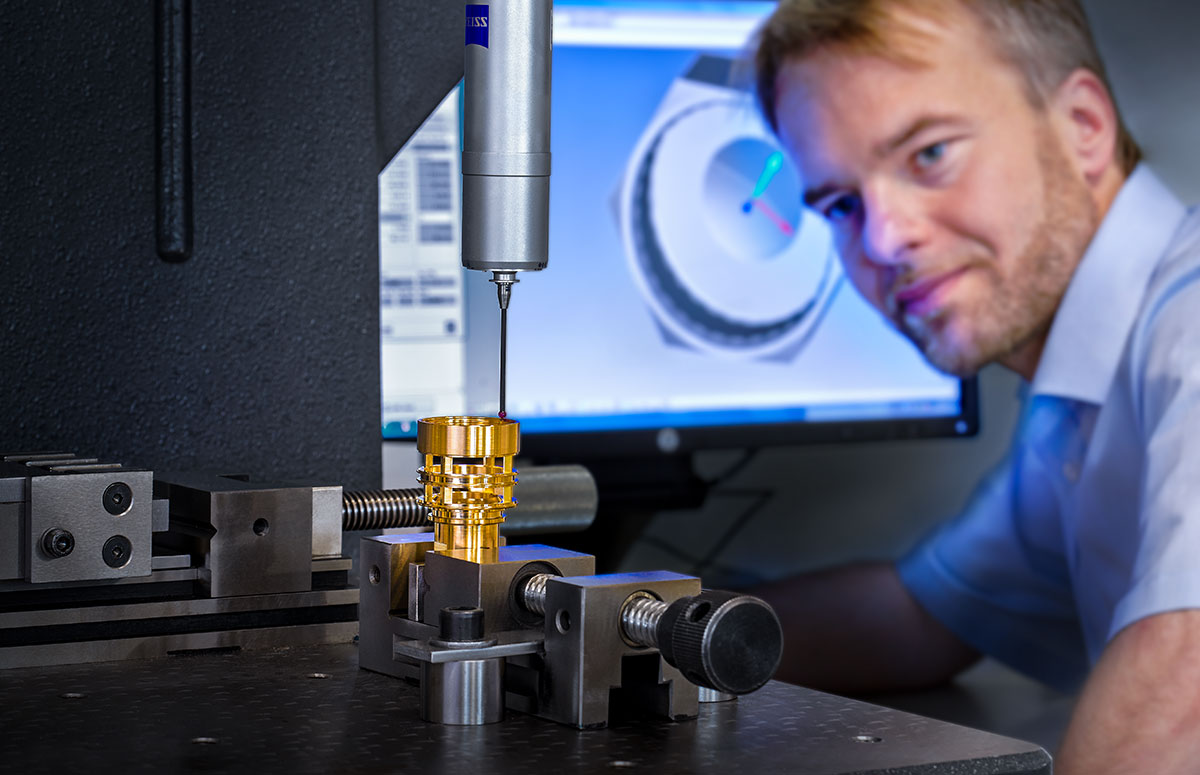

For us, the perfect turned part consists of more than metal. It comprises a great deal more than that: When you source precision turned parts from Firner Trautwein, you access a combination of the most modern machines and systems, the finest of skilled employees and tried-and-tested processes. This enables us to assure the highest standards of quality at cost-effective terms and conditions.

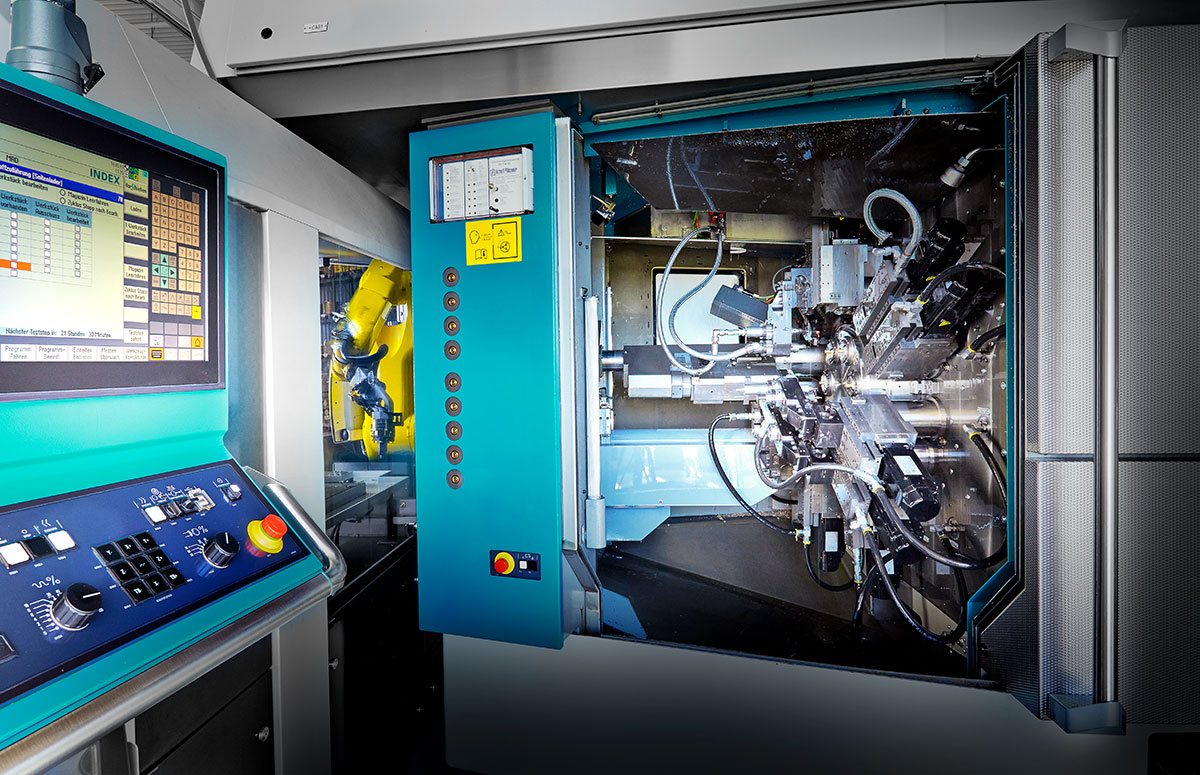

With our CNC single-spindle, multi-spindle and automatic rotary indexing machines , Firner Trautwein works across a range of diameters spanning approx. 3 mm to 65 mm, and chucking components with diameters of up to 150 mm. We machine brass, steel, stainless steel and aluminium alloys across a vast range of different material qualities. If you so wish, we shall be pleased to guide you through the assembly and installation work. We would be delighted to have a chance to impress you with our professional skills!

OUR PRECISION TURNED PARTS ARE USED

PRIMARILY IN THESE SECTORS:

- Electrical engineering / electronics

- Automotive

- Communications technology

- Sanitary technology

- Building technology

- Medical technology

- Hydraulics

- Mechanical engineering

IN ADDITION, WE CAN PERFORM

OTHER PRODUCTION PROCESSES FOR YOU:

- Surface coating

- Heat treatment

- Flanging

- Surface welding of contact materials

- Nut-running

- Building of sub-assemblies

Machinery

Equipped for the best

With our ultra-modern range of in-house machinery, we are able to satisfy every requirement relating to ultra-precise turned parts. Speed, flexibility and cost-effectiveness, from short to long production runs. Our spectrum of machining processes ranges from single-spindle and multi-spindle turning machines to automatic rotary indexing machines, transfer machines and special-purpose machines, and even includes deburring and assembly systems.

Of course, any machine is only ever as good as the personnel that operate it. At Firner Trautwein, you place your confidence in the hands of an exceptionally capable and experienced team of people. This is what enables us to achieve a final result that is nothing less than ... your perfect turned part!

IN-HOUSE MACHINERY

- CNC single-spindle automatic turning machines

- CNC multi-spindle automatic turning machines

- Cam-controlled multi-spindle automatic turning machines

- Automatic rotary indexing machines

- Automatic deburring machines

- Transfer machines and special machines

- Further processing machines

- Automatic assembly machines

FT Service

Satisfied all round!?

The motto at Firner Trautwein is ... turned parts first, last and all round! With our experience from countless projects for customers from many different industry sectors, we have acquired a great deal of expertise - knowledge that makes us the perfect advisor and partner in relation to all questions relating to our precision manufacturing capability.

Even at an early stage of development, we would be delighted to sit down with you to discuss the project you are planning. You can benefit from our competence: What parts do you need and how many, and where are they later going to go into service? Together, we can then agree a process sequence that will lead to your desired turned part. If you so wish, this can also include assembly.

To ensure that you are all-round satisfied with us, we can of course remain by your side as a partner thereafter: Firner Trautwein will not leave you out in the cold. We would like to know how our products perform in your application, whether further improvements would be a good idea or, to summarise that in simple terms, to know where the journey goes next. With Firner Trautwein, you are placing your confidence in an expert that understands precision manufacturing to be an all-inclusive process - and something to which we are personally committed.

Contact us to arrange a meeting.

We shall be pleased to share our experience with you. Call us or simply fill in the form below and we shall get in touch with you as quickly as possible.